Designed for Reliability: PROFINET in Process Automation

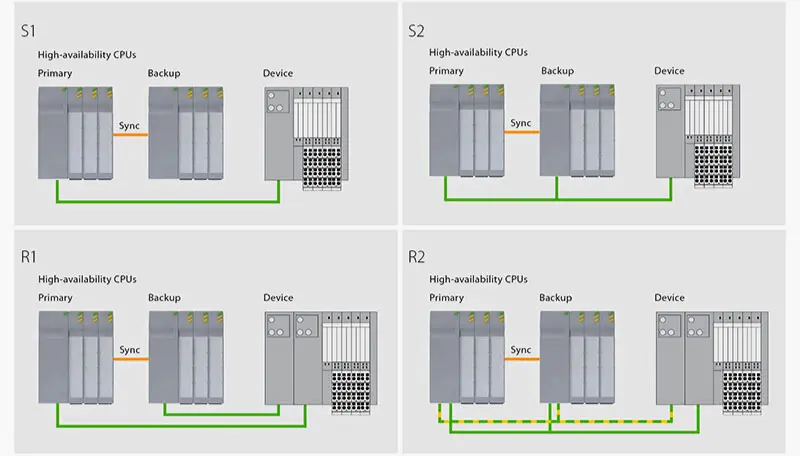

Modern automation systems in all industries increasingly depend on continuous operation. Whether in manufacturing, logistics, food processing, or energy — even short downtime can lead to productivity loss, quality issues, or safety risks. That’s why redundancy is no longer just a high-end feature — it’s becoming a standard requirement. Redundant controllers and field-level devices help maintain seamless process continuity and improve overall system availability.

Combining PROFINET S2 Redundancy with IO-Link

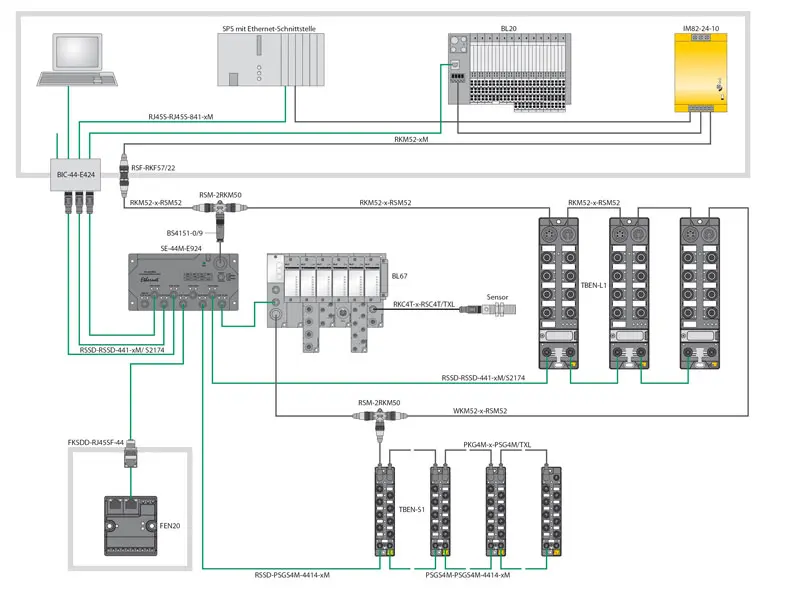

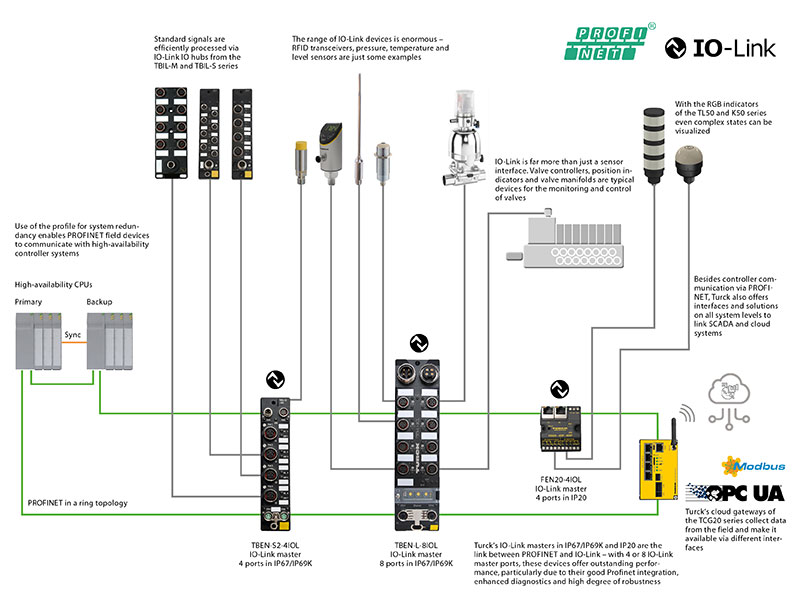

Turck’s I/O modules with PROFINET S2 redundancy support enable seamless communication with both primary and backup controllers over a single connection. This enhances system availability in process environments where downtime is not acceptable.

When combined with IO-Link, these modules allow for end-to-end digital communication with field devices such as sensors, valve islands, and I/O hubs. IO-Link simplifies installation by using standard unshielded cables for both data transmission and power supply, while also providing advanced diagnostics and parameterization capabilities.

This combination of PROFINET redundancy and IO-Link integration offers a robust, scalable solution for process automation systems that demand reliability, transparency, and reduced wiring complexity.

Considering PROFINET with System Redundancy?

Tell us about your application — our team will help configure the best solution for your needs.