📌 The Challenge

A leading brewery encountered recurring issues where robotic crate loaders failed to insert all 20 bottles. These underfilled crates often went unnoticed until they reached customers — resulting in complaints, returns, and inefficiencies. Manual inspection was too slow and unreliable. An automated, real-time solution was needed.

🔧 Complete Solution

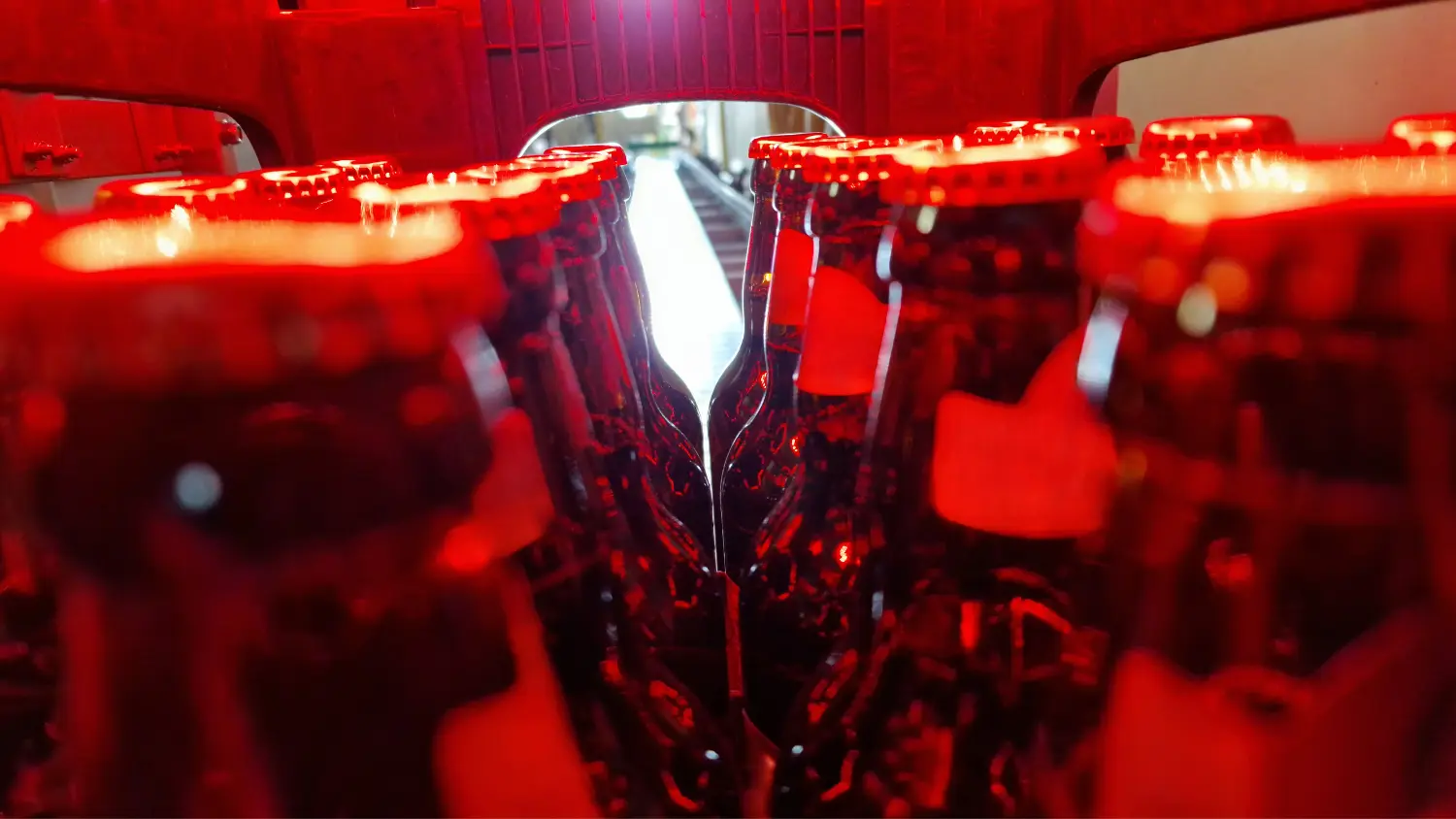

We designed and installed a smart vision system that combines high-performance imaging, synchronized lighting, and trigger logic — all built for industrial robustness and precision. The system inspects an entire crate in a single image, detecting not only missing bottles but also bottles without caps.

Need a reliable way to verify crate completeness?

Tell us about your application — our team will help configure the best solution for your needs.

Vision Sensor: Banner iVu Plus TG

At the heart of the system is the iVu Plus TG image sensor — a powerful, self-contained vision sensor with integrated display and processing.

Captures a high-contrast image of the entire crate and runs an onboard inspection algorithm to count bottle caps. If fewer than 20 caps are detected — or if a bottle lacks a cap — it triggers a fail signal in real time.

Key specs:

- 752×480 pixel CMOS sensor

- Up to 60 fps image acquisition

- Built-in 6 mm lens and red LED ring light

- Ethernet, USB, and discrete I/O connectivity

- Integrated touch display or remote Vision Manager software control

- IP67-rated housing for industrial environments

Illumination: Red LED Strip – Banner WLF12 Pro

To ensure consistent and accurate cap detection, we used an industrial-grade LED light strip with focused red output.

Mounted inside a custom-built aluminum light hood, the WLF12 Pro generates high-contrast red illumination that enhances the visibility of cap edges. This ring-like reflection is key to accurate detection by the iVu vision sensor. The enclosed lighting environment also isolates the imaging area from external interference, maintaining consistent image quality.

Key specs:

- Programmable RGB LEDs — configured to emit red illumination for optimal contrast in vision tasks

- Fully sealed design (IP66/IP67/IP69K) — suitable for washdown and damp environments

- Cut-to-length flexibility — customized to match the crate’s inspection zone

- 120° beam angle — delivers wide, even light distribution across the full crate

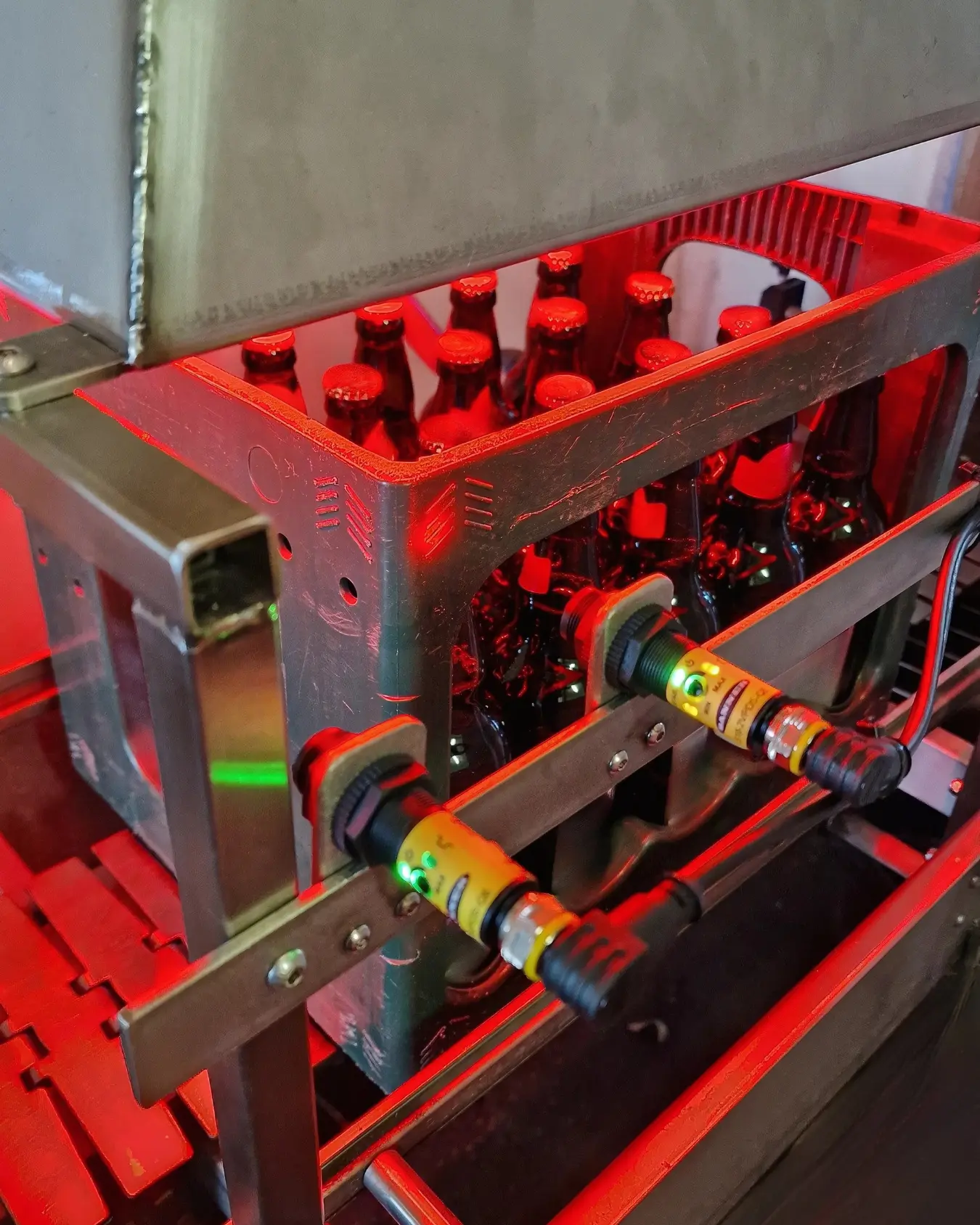

Triggering Logic: Dual Photoelectric Sensors – Banner S18-2 Series

Two S18-2VPDS-Q8 photoelectric diffuse-mode sensors coordinate crate detection and camera activation.

Sensor 1: Detects crate entry → Activates the LED lighting

Sensor 2: Confirms crate alignment under the camera → Triggers image capture by the iVu sensor

This logic ensures accurate timing adjustments and minimal false triggers — maximizing reliability and minimizing system wear.

Key specs:

- Operating range: up to 300 mm

- Voltage: 10–30 V DC, PNP output

- Bright visible red LED for precise alignment

- IP67-rated cylindrical body (M18)