The Solution

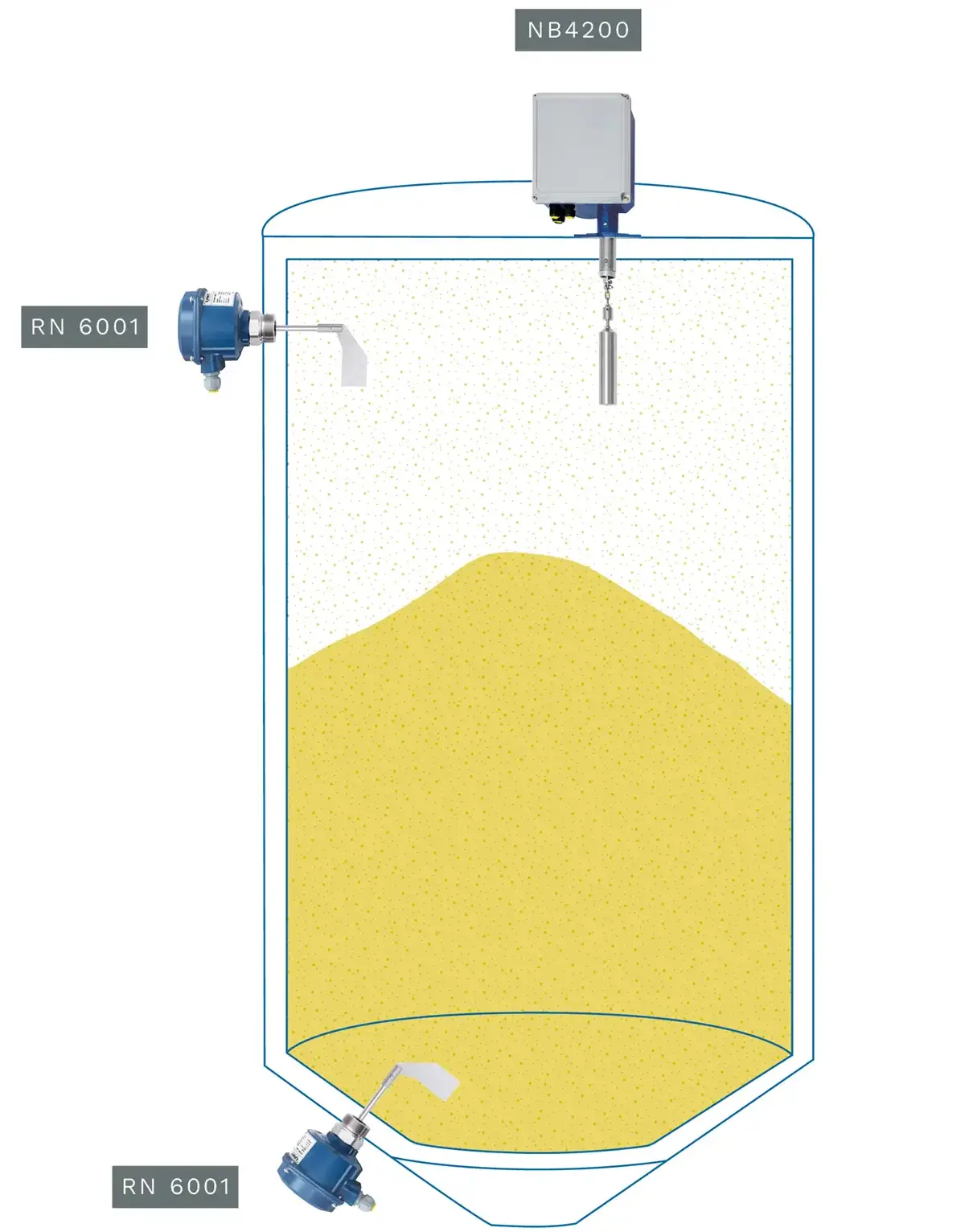

Designed specifically for dusty, explosion-prone grain silos, this sensor system ensures safe and efficient operation by combining continuous level monitoring, point level detection, and visual status indication in one integrated solution. With ATEX/IECEx approvals for use in Zone 20/21 environments and a measuring range of up to 30 meters, it meets all key requirements for reliable level control in high-dust, high-risk applications — even under conditions of overpressure during silo filling.

- NivoBob® NB 4200 provides reliable, continuous measurement — even in tall, dusty, or low-reflectivity silos.

- Rotonivo® RN series delivers precise point level detection for overfill or empty alerts, with SIL 2 safety compliance.

- NivoLED® NL 9000 offers 360° visual status indication — highly visible even in dust-heavy environments.

The system is easy to integrate into existing PLC or SCADA control architectures and designed for long-term operation with minimal maintenance.

Configure the right level monitoring system for your silo

Tell us a bit about your application — materials, silo type, and zone classification — and our team will recommend the optimal sensor setup for safe and efficient operation.

Competitive pricing

Listing your product pricing helps potential customers quickly determine if it fits their budget and needs.

NivoBob® NB 4200

Continuous level measurement for grain silo

Learn more- Measuring range up to 30 m

- Reliable electromechanical operation, unaffected by dust or buildup

- Integrated cable cleaning for minimal maintenance

- Certified for Zone 20/21 (ATEX, IECEx

Rotonivo® RN 6001

Heavy-duty point level detection for standard grain silos

Learn more- Rotary paddle switch for full, empty, or demand detection

- Designed for bulk materials with varying densities and flow behavior

- Robust aluminum housing with process temperature range up to +110 °C

- SIL 2 compliant and certified for Zone 20/21/22

Rotonivo® RN 3001

Compact point level switch for small vessels and tight installations

Learn more- Shortened, space-saving construction for limited mounting conditions

- Reliable detection of fine, dry, and lightweight materials

- IP66/IP68-rated plastic housing for dust-tight and moisture-resistant performance

- SIL 2 certified and ATEX-approved for Zone 20/21/22

NivoLED® NL 9000

360° visual status indication in explosive zones

Learn more- Dual-color LED indication for clear process feedback

- PVDF housing with IP66/NEMA 4X protection — ideal for harsh environments

- Certified for use in dust and gas zones (Zone 21 / Zone 2)

- Simple mounting on silos, cabinets, or panels