Free-beam radar sensors

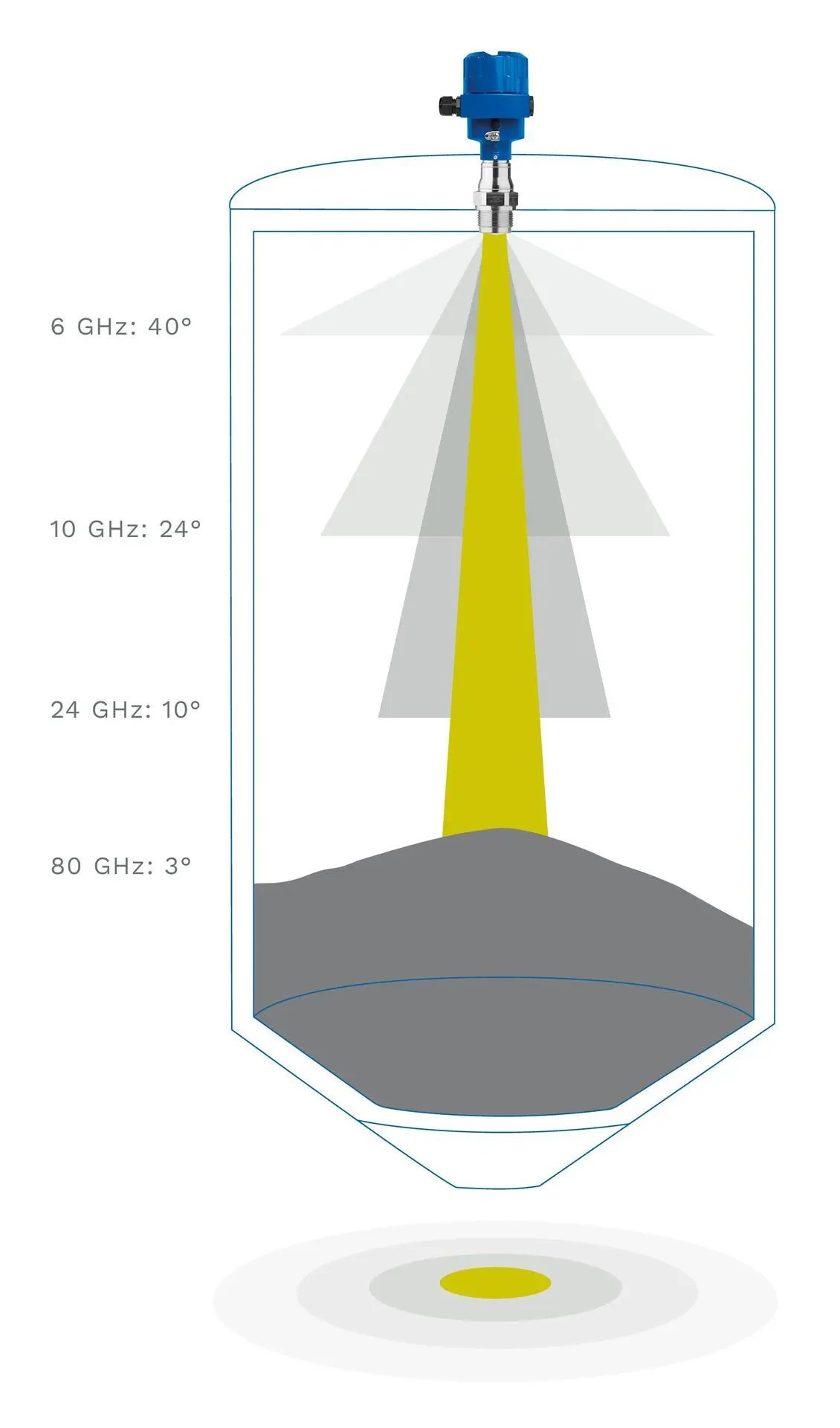

They operate contactlessly and use electromagnetic waves that are transmitted directly to the medium via special antennas. The frequency used is a key performance factor – it influences how precisely and reliably the fill level in process or storage containers can be measured.

High-frequency technology

Radar sensors with high frequencies, such as 80 GHz technology, can be designed compactly, have small beam angles of up to 3°, and excellent reflection properties. This enables them to deliver precise and reliable measurement results, even in complex tank geometries or in narrow shafts and pipes.

Typical applications

Ideal for liquids and bulk materials in silos, tanks and open containers, especially where non-contact measurements are preferred due to hygiene or process requirements.

Explore Free-beam radar sensors

Guided radar sensors

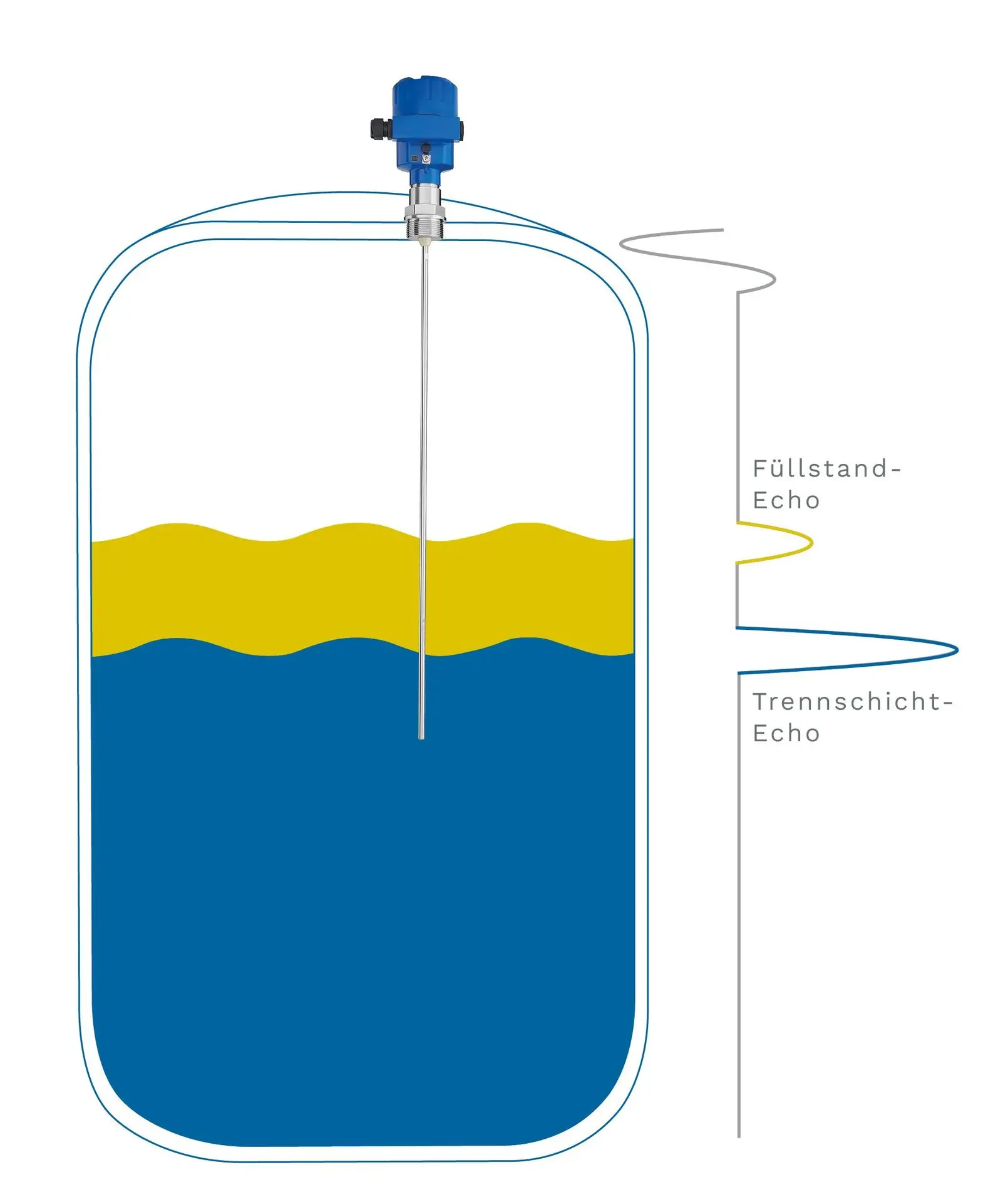

With this technology, the high-frequency signal is transmitted directly to the medium via a guided probe – a rod or rope. The so-called TDR or GWR measurement is based on the principle of guided microwaves, in which the probe acts as a waveguide. Direct contact with the medium offers advantages in complex applications: Even in the presence of foam, steam, or weak reflections, the measurement delivers stable and precise values – ideal for demanding process conditions.

Low frequency technology

Guided radar sensors often operate at very low frequencies (e.g., 1 GHz), making them particularly insensitive to dust, buildup, foam, or vapor. This makes them ideal for applications involving moving surfaces or interface measurements.

Customizable probe types

Different variants such as rod probes, rope probes or coated probes (e.g. PA) allow flexible adaptation to specific process requirements.

Typical applications

They are particularly suitable for demanding process environments such as dusty silos or tanks with aggressive media.

Explore Guided radar sensors

Need help selecting the right model?

Tell us about your application — our team will help configure the best solution for your needs.

Advantages of Radar Technology

High Accuracy

Delivers precise results, even under extreme temperatures, pressure, or aggressive media.

Maintenance-Free

Non-contact measurement prevents wear and minimizes maintenance costs.

Contamination Resistant

Reliable even with dirt or deposits; no frequent cleaning needed.

Unaffected by Environment

Performs accurately in fog, rain, wind, vacuum, and high/low temperatures.

Easy to Use

Quick setup and configuration via tools like UWT LevelApp.

No Dead Zone

Measures reliably up to the antenna, even during flooding.

Focused Signal

80 GHz radar isolates measurements from interference in narrow or obstructed areas.

Versatile Applications

Suitable for solids, liquids, silos, tanks, and outdoor environments.