Challenges in the Synthetics Industry

Although plastics are versatile materials, the synthetics industry faces several challenges affecting production efficiency and sustainability:

- Environmental requirements and sustainability – The demand for a smaller environmental footprint and eco-friendly alternatives increases the need for more precise resource management.

- Recycling and waste reduction – Globally, there is an increasing emphasis on improving the lifecycle of synthetic materials and optimizing waste management.

- Material storage and transport – Efficient management of granules, liquids, and other raw materials is essential to prevent overfilling or stock shortages.

- Continuous production – Accurate level control is crucial to avoid production downtime and ensure a smooth process flow.

Importance of Level Measurement in the Synthetics Industry

In the manufacturing and processing of synthetic materials, precise level measurement helps ensure product quality, minimize downtime, and improve process efficiency.

Level sensors are used for:

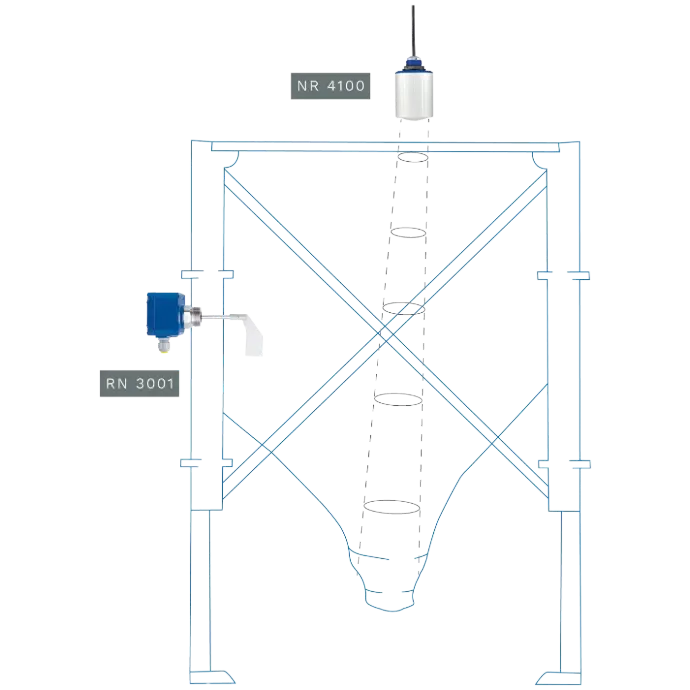

- Raw material storage – Monitoring the level of granules, powders, and liquids to ensure timely replenishment.

- Production processes – Accurate material quantity monitoring ensures consistent product quality.

- Logistics and supply chain – Helps optimize resource distribution and avoid unexpected production disruptions.

Considering the diversity of materials and various applications, choosing the right level measurement technology is crucial.

UWT Brochure – Detailed insights into level measurement solutions for the synthetics industry.

Don’t Let Measurement Inaccuracies Disrupt Your Production!

Contact us to discuss the best level measurement solution for your needs!

Contact Us!

Increased Operational Safety

The use of reliable sensors and a robust

communication network minimises the risk of

measurement errors and technical failures.

Cost Savings

The precise level measurement and prevention of overfilling reduce material losses and production downtime.

Efficiency Improvement

By centralizing the capture and real-time display of fill levels, production processes can be better planned and resources optimally utilized.

Benefits You Can Expect