Challenges in Modern Sensing Applications:

- Irregular shapes (e.g., polybags, folded flaps, mailers)

- High-speed conveyor lines requiring sub-millisecond response times

- Harsh industrial environments (dust, washdowns, ESD risk)

- Variable materials (transparent, reflective, or perforated surfaces)

What Is Leading Edge Detection?

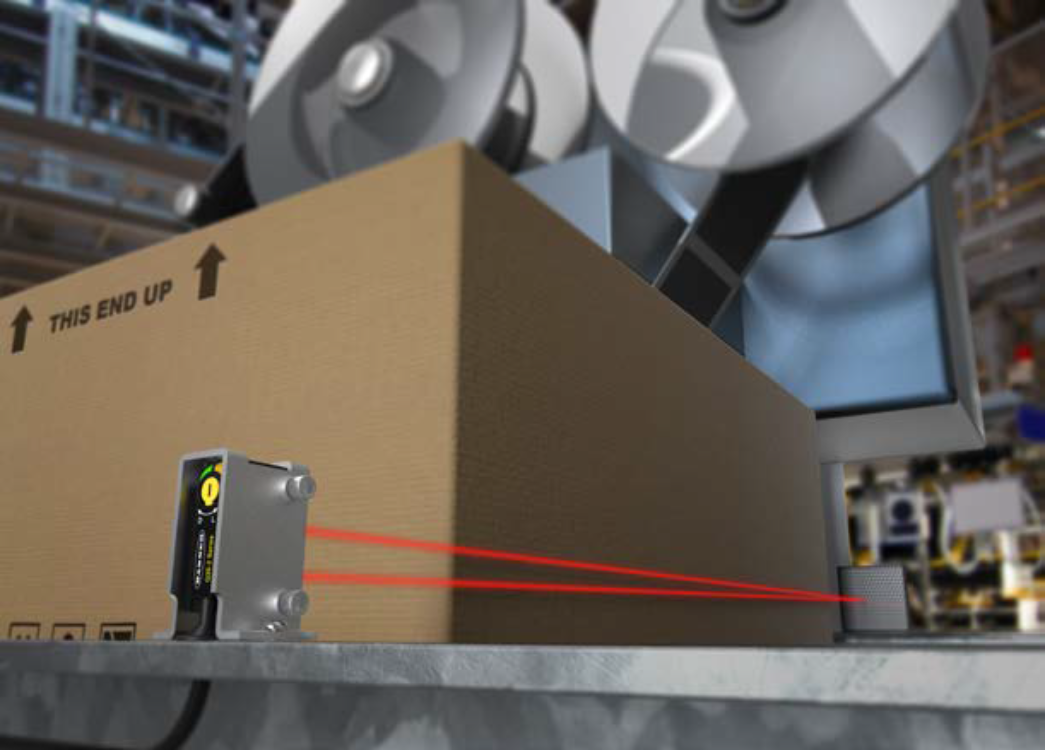

Leading edge detection is the process of sensing the very front of a moving object as it enters a monitored area, typically a conveyor segment. Correctly identifying this "leading edge" enables actions such as sorting, scanning, merging, or stopping. With modern packaging becoming more irregular—such as envelopes, tubes, polybags, or blister packs—the sensing technology must adapt to ensure consistent, fast, and reliable detection.

Need help with Leading Edge Detection?

Tell us about your conveyor type, packaging challenges, or sensing requirements — and our specialists will help you choose the right solution.

Optimizing Leading Edge Detection with Banner Engineering Sensors:

QS18 and Q20 Polarized Retroreflective Photoelectric Sensors

Compact and cost-efficient, these retroreflective photoelectric sensors are optimized for detecting boxes, totes, and other standard targets. They deliver 850 µs response time with reliable optical performance even at close range. Polarization ensures accurate detection of reflective surfaces, and the single-sided wiring reduces installation time and complexity.

Key benefits:

- Stable detection of reflective or glossy objects

- Simplified installation with no need for opposite-side wiring

- Ideal for conveyors with side rails

- Compact housing and flexible mounting options

- Suitable for general packaging and logistics applications

B25 Wide Beam Small Object Detection Sensor

Wide beam coverage ensures stable detection of polybags, mailers, and irregular-shaped packages. The 25 mm sensing beam suppresses false signals caused by holes, flaps, or folds, making it ideal for lightweight or unstable items. IO-Link support enables remote configuration and diagnostics.

Key benefits:

- Uniform detection across wide, irregular targets

- Fast 0.5 ms response time

- Detection as small as 3 mm at 1.1 m

- IO-Link integration for diagnostics and setup

- IP67-rated for industrial environments

Q76E Wide Beam Retroreflective Sensor

Engineered for detecting large or irregular items such as pallets or shrink-wrapped loads. Offers up to 4 m range with dual sensitivity settings for versatile detection. IP69-rated construction ensures durability in washdown zones and heavy-duty environments.

Key benefits:

- Wide sensing beam for large or unstable targets

- Adjustable sensitivity for difficult-to-detect packaging

- IP67/IP69 enclosure for harsh conditions

- Visual alignment aid with bright LEDs

- Configurable via push-button or IO-Link

LX Series Area Detection

Crosshatched beam array provides reliable detection of thin or flat items such as envelopes, blister packs, or films. Extremely fast response (from 0.8 ms) enables high-speed applications with consistent results, even for objects as thin as 1 mm.

Key benefits:

- Detection of very thin or flat materials

- Large sensing area maintains coverage despite object position

- Crosshatched beam for increased accuracy

- Multiple array lengths for different installation needs

- Fast response time supports high-speed lines

TTR Roller Conveyor Sensor

Installs between conveyor rollers, enabling detection without requiring side mounting. Designed for letters, small packages, or polybags, especially where space or mounting constraints exist. Available in customizable lengths and beam counts.

Key benefits:

- Fits directly between rollers with no extra mounting hardware

- Detects wide range of item types and sizes

- Spring-loaded ends for easier alignment

- Rugged aluminum housing resists damage

- Designed for conveyors without side access