Why Workplaces Need Safety Light Curtains

Operators frequently work near hazardous zones such as robotic arms, presses, and automated conveyors. Inadequate safeguarding can lead to severe injuries, while rigid guarding solutions often cause:

- Reduced accessibility for operators and maintenance staff.

- Unplanned downtime due to difficult adjustments or misalignment.

- Higher maintenance costs from damaged or improperly installed barriers.

- Limited flexibility when production lines or tooling need to be reconfigured.

How the S4B Series Solves These Challenges

The S4B series is designed to balance safety, uptime, and flexibility. It enables:

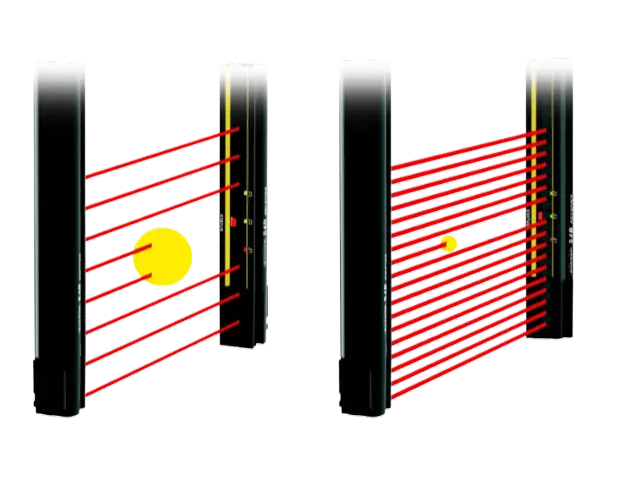

- Reliable detection of fingers or hands depending on the application risk.

- Quick adaptation to new layouts with muting and blanking accessories.

- Early maintenance alerts, preventing downtime caused by dust or misalignment.

- Simplified installation, saving time and reducing wiring errors.

Need help selecting the right model?

Tell us about your application — our team will help configure the best solution for your needs.

S4B Features and Advantages

Streamlined Installation with Auto-Cascading

- Automatically recognizes additional curtain segments.

- Reduces wiring complexity and installation time.

- Minimal response time impact allows closer installation to machines, optimizing floor space.

High-Resolution Protection Options

- 14 mm resolution for precise finger detection in high-risk zones.

- 30 mm resolution for hand-level detection in less critical areas.

- Flexibility to choose based on risk assessment.

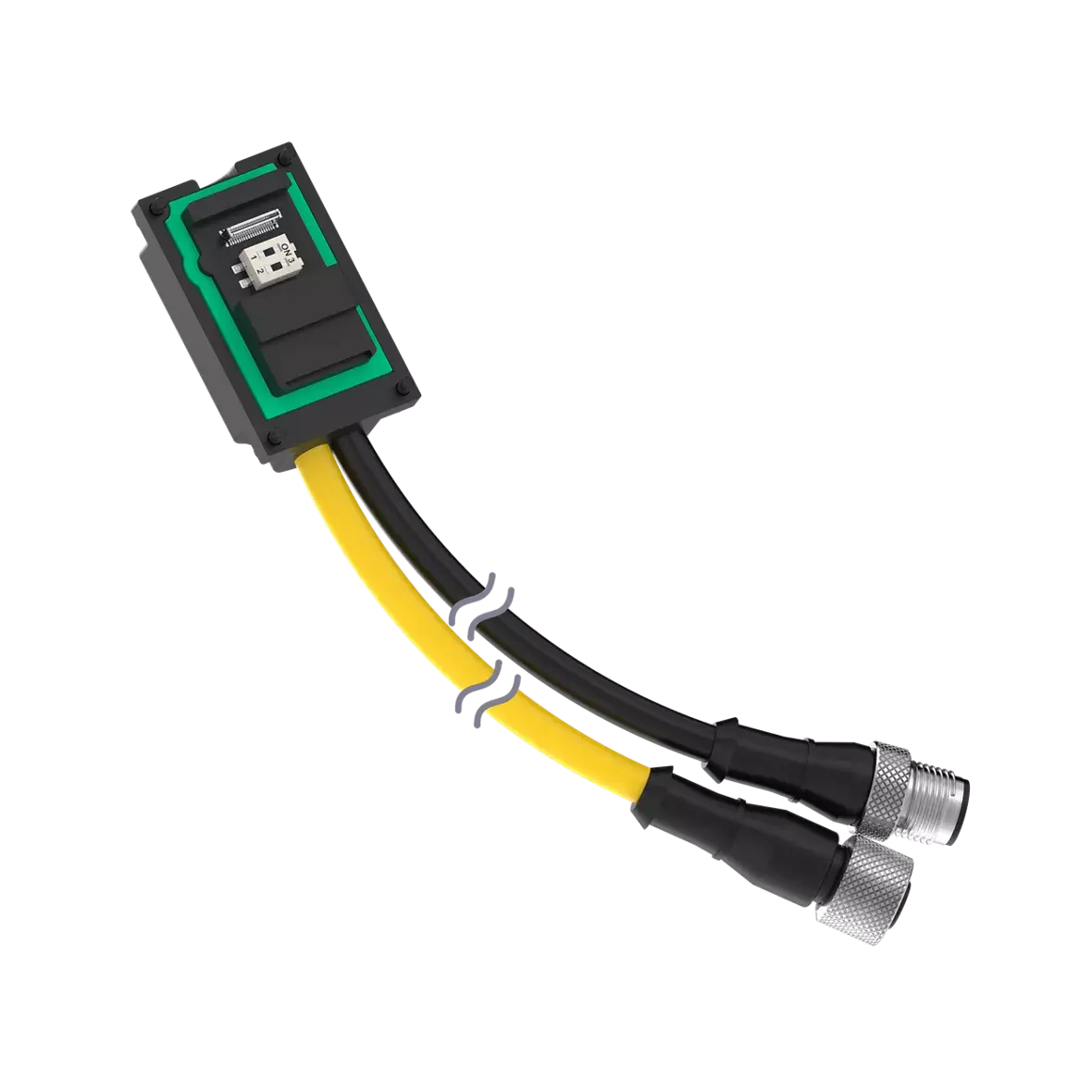

Efficient Maintenance with Specially Designed Cordsets

- Color-coded connectors (yellow for cascading, black for controller).

- Supports up to four pairs, even with mixed lengths/resolutions.

- Quick cordset replacement avoids full device swap, minimizing downtime.

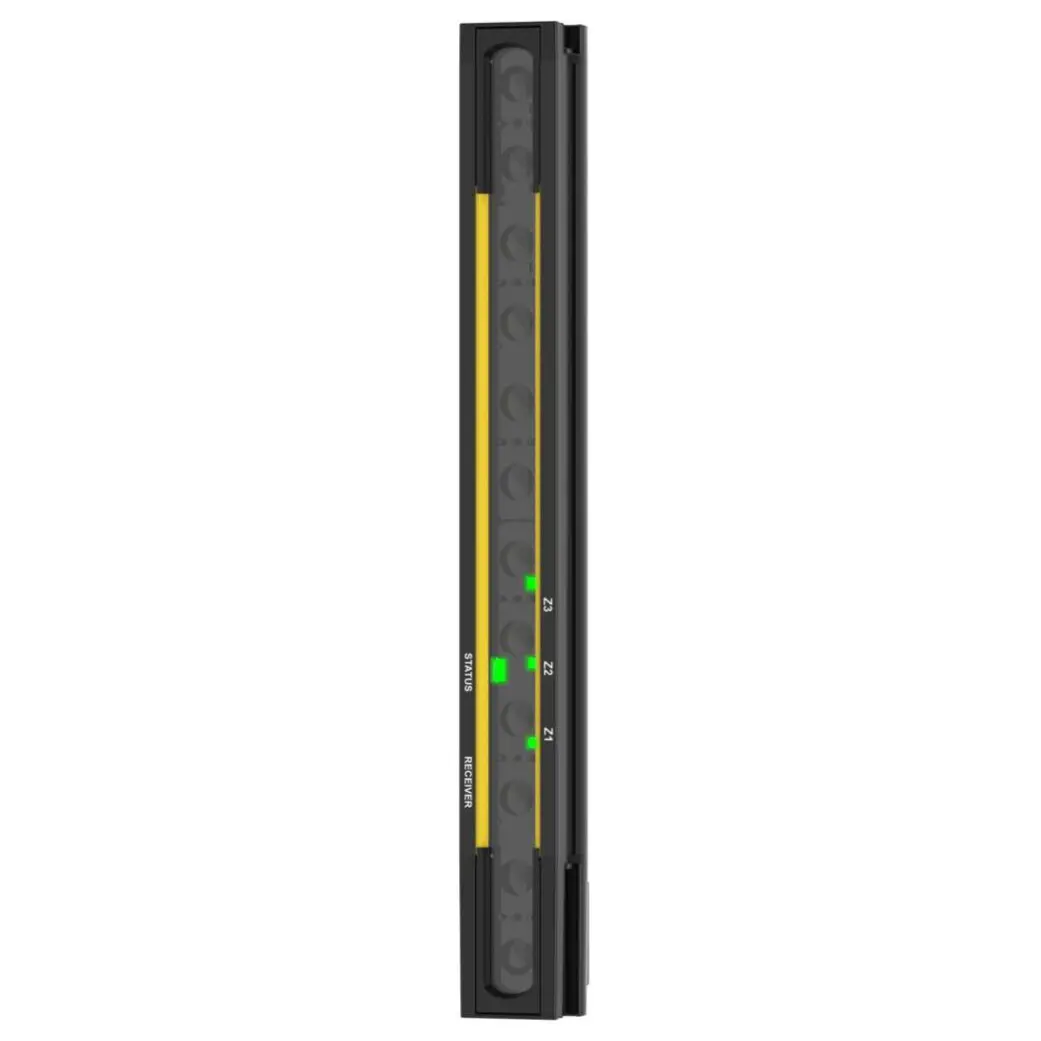

Advanced Diagnostics and Predictive Maintenance

- Alignment indicators (green, yellow, red) for clear setup status.

- Weak beam alerts via PLC/HMI connection warn when cleaning is needed.

- Recessed optical window reduces damage in harsh environments.

Flexible Integration with Muting and Blanking Accessories

- AMuting kits (L, T, and X configurations) allow safe passage of pallets or materials without halting machines.

- Muting junction box consolidates safety and non-safety wiring into one block.

- Remote Fixed Blanking allows exclusion of zones via key-turn switch — no DIP switch access or power cycling needed.

- Built-in ±1 beam tolerance prevents false trips in high-vibration settings.

S4B Series models

Emitter 30mm Resolution

(length: 300mm)

392.00 €

- Resolution: 30 mm (hand protection)

- Operating range: 0.1 m … 12 m

- Response time: 7.5–30 ms (depending on system length)

- Available lengths: 300 … 1800 mm

- Ingress protection: IP65

- Operating temp.: –20 °C … +55 °C

Receiver 30 mm Resolution

(length: 300mm)

479.00 €

- Resolution: 30 mm (hand protection)

- Operating range: 0.1 m … 12 m

- Response time: 7.5–30 ms (depending on system length)

- Available lengths: 300 … 1800 mm

- Outputs: 2x OSSD, 0.5 A each (PNP)

- Ingress protection: IP65

- Operating temp.: –20 °C … +55 °C

Emitter 14 mm Resolution

(length: 300mm)

514.00 €

- Resolution: 14 mm (finger protection)

- Operating range: 0.1 m … 12 m

- Response time: 7.5–30 ms (depending on system length)

- Available lengths: 300 … 1800 mm

- Ingress protection: IP65

- Operating temp.: –20 °C … +55 °C

Receiver 14 mm Resolution

(length: 300mm)

629.00 €

- Resolution: 14 mm (finger protection)

- Operating range: 0.1 m … 12 m

- Response time: 7.5–30 ms (depending on system length)

- Available lengths: 300 … 1800 mm

- Outputs: 2x OSSD, 0.5 A each (PNP)

- Ingress protection: IP65

- Operating temp.: –20 °C … +55 °C