Why Safety Laser Scanners Are Essential ?

Conventional guarding methods such as fencing or light curtains can be inflexible, especially for systems that involve moving machinery or require regular human access. Safety laser scanners provide dynamic, non-contact protection, enabling safer workflows without restricting efficiency or mobility. By defining safety and warning zones around hazardous areas, these scanners automatically stop machinery or mobile platforms when a person or object enters the protected field—reducing the risk of injury and unplanned downtime.

How SX5 Scanners Work

SX5 scanners use Class 1 eye-safe laser beams with Time-of-Flight technology to monitor a 275° field of view. They compare this area against user-defined safety and warning zones, and if someone enters a protected zone, the scanner immediately signals the machine to stop.

Key benefits:

- Operating range up to 5 m safety zone and 40 m warning zone

- Up to 128 configurable zones with muting and zone switching options

- Integrated or remote configuration (USB, Ethernet, Bluetooth)

- Models with color display for quick diagnostics available

- Complies with SIL 2 and PL d safety requirements

Need help selecting the right model?

Tell us about your application — our team will help configure the best solution for your needs.

Proven Solutions that Keep Operations Running

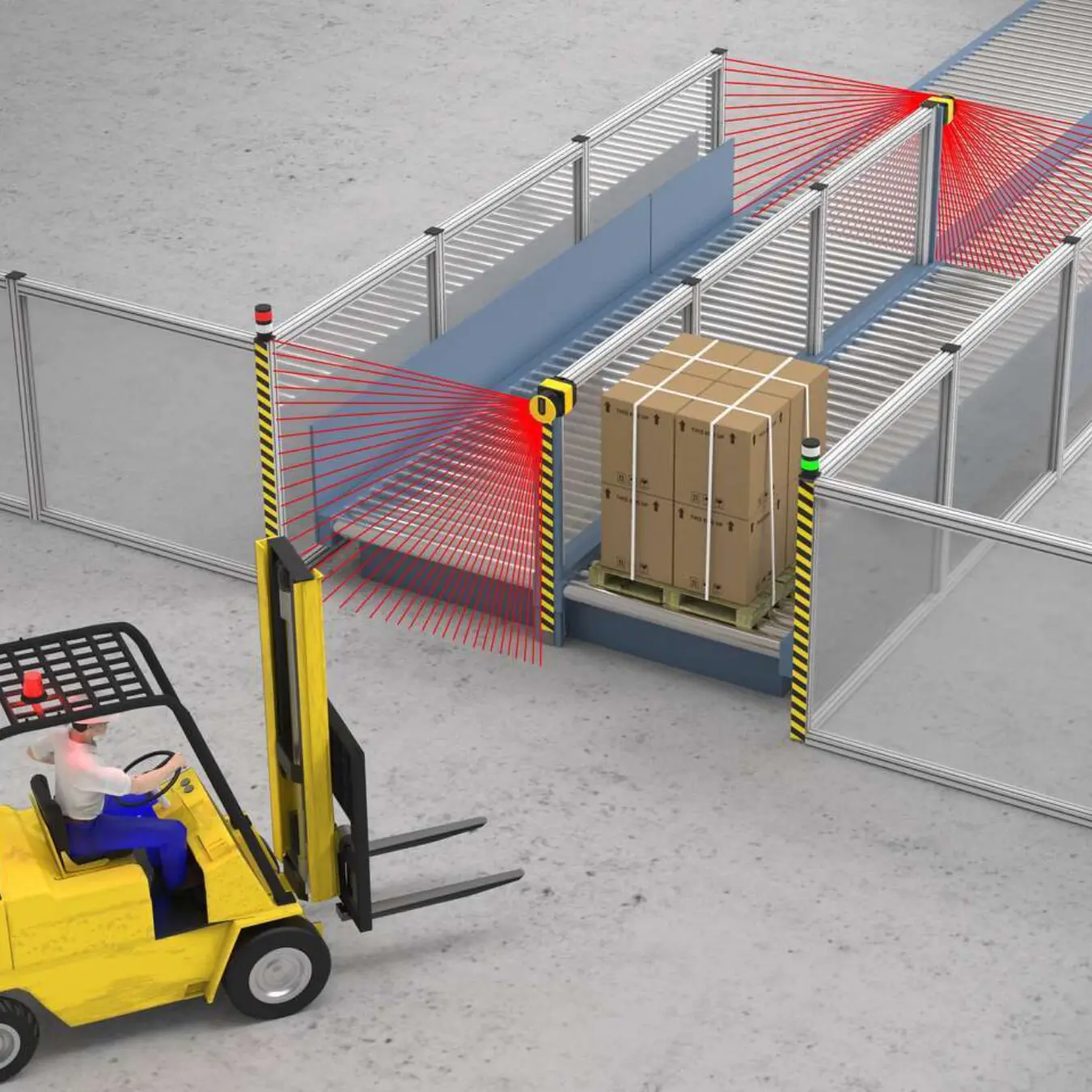

Safeguarding a Pallet Transfer Conveyor

Pallet transfer conveyors require protection at loading and unloading points where physical barriers would disrupt flow. SX5 safety scanners provide non-contact safeguarding by scanning across multiple access points and down to the floor, detecting anyone entering the zone.

Using dynamic zone switching, the SX5 adapts to pallet movement—activating only the necessary protective zones while keeping other lanes open. This ensures safety without reducing throughput. Compact design, intuitive setup software, and strong immunity to dust and light interference make the SX5 both easy to deploy and reliable in demanding conditions.

Protecting a Robotic Weld Cell

Robotic weld cells need open access for material handling, which can expose operators to motion, sparks, and spatter. Mounted near loading zones, SX5 scanners establish both warning zones and safety zones. Entering the warning zone triggers a visual alert, while entering the safety zone immediately halts the robot.

The scanner’s compact form, configurable zones, and resistance to harsh welding environments provide flexible and dependable protection. With straightforward software setup and clear diagnostic feedback, the SX5 helps maintain operator safety while keeping the weld cell productive.

SX5 Series models

SX5-B6

4204.00 €

-

Range (depending on resolution) :

30 mm – 2.5 m

40 mm – 3 m

50 mm – 4 m

70/150 mm – 5.5 m - Max. Zone Sets: 6

- Master / Remote:

- Removable Memory:

- Speed Monitoring :

- Max. OSSD Outputs: 1 × 2 OSSD

SX5-M10

5388.00 €

-

Range (depending on resolution) :

30 mm – 2.5 m

40 mm – 3 m

50 mm – 4 m

70/150 mm – 5.5 m - Max. Zone Sets: 10

- Master / Remote: Master (up to 3 remotes)

- Removable Memory: SXA-RM-10

- Speed Monitoring :

- Max. OSSD Outputs: 2 × 2 OSSD

SX5-M70

5497.00 €

-

Range (depending on resolution) :

30 mm – 2.5 m

40 mm – 3 m

50 mm – 4 m

70/150 mm – 5.5 m - Max. Zone Sets: 70

- Master / Remote: Master (up to 3 remotes)

- Removable Memory: SXA-RM-70

- Speed Monitoring :

- Max. OSSD Outputs: 3 × 2 OSSD

SX5-ME70

5820.00 €

-

Range (depending on resolution) :

30 mm – 2.5 m

40 mm – 3 m

50 mm – 4 m

70/150 mm – 5.5 m - Max. Zone Sets: 70

- Master / Remote: Master (up to 3 remotes)

- Removable Memory: SXA-RM-70

- Speed Monitoring :

- Max. OSSD Outputs: 3 × 2 OSSD

SX5-R

4204.00 €

-

Range (depending on resolution) :

30 mm – 2.5 m

40 mm – 3 m

50 mm – 4 m

70/150 mm – 5.5 m - Max. Zone Sets: Depending on master

- Master / Remote: Remote

- Removable Memory:

- Speed Monitoring :

- Max. OSSD Outputs: