Wireless Production Counting System for Dairy Manufacturing

Automated monitoring system for 4 production lines with wireless Modbus RTU connectivity, providing accurate production counting, defect tracking, and operator productivity analysis.

Client Challenges

No Operator Productivity Data

Unknown how many products each operator packages per shift.

Manual Defect Tracking

Defects, repackaged items, and laboratory samples not systematically recorded. Data written on paper or not tracked at all.

No Production Overview

No information on how many units of each product were manufactured per day, week, or month. Planning based on assumptions.

Installed Solution

How the System Works

Product Counting

Optical sensors BANNER QS18VP6AF250Q8 with background suppression (BGS) function were installed on four production lines to automatically count products passing through.

Quality Control Interface

BANNER K50PTAMGRY3Q pushbuttons (IP69K rated for harsh environments) allow operators to flag defective products. The programmable button provides instant visual feedback — changing from pulsing green to red when pressed, so operators always know their input was registered.

Wireless Data Transmission

Banner

R70SR2MQ

wireless transmitters send all sensor and button data to the central HMI panel using Modbus RTU RS485 protocol at 2.4GHz frequency. The system uses a star topology: 4 transmitters feeding into one central receiver.

Simplified Installation

Signal splitters (VB2-FSM4.4-2FKM4 and CSB-M1250M1250-T) dramatically reduce cable requirements and eliminate the need for traditional electrical panels — cutting installation time and complexity.

Operator Display

All production data is displayed on the Turck TX710-P3CV01 HMI panel — a rugged 7-inch touchscreen designed for industrial environments. Operators can view real-time counts, track defects, and access production reports from one central location.

System Architecture

From improved operational visibility to stronger data-driven decision-making, the achieved results reflect a structured approach to process optimization and long-term business efficiency, with a scalable system architecture that can be easily extended across additional production lines to support sustainable and long-term growth.

Automatic output tracking per operator and production line, creating a clear, objective basis for performance evaluation.

Defects and reworked products are logged digitally with timestamps — eliminating manual paperwork and human error.

Accurate daily, weekly, and monthly production data available for analysis, reporting, and operational planning.

Up to three users can monitor production live from the office, ensuring full visibility of shop-floor activity.

Results Achieved

HMI Functionality

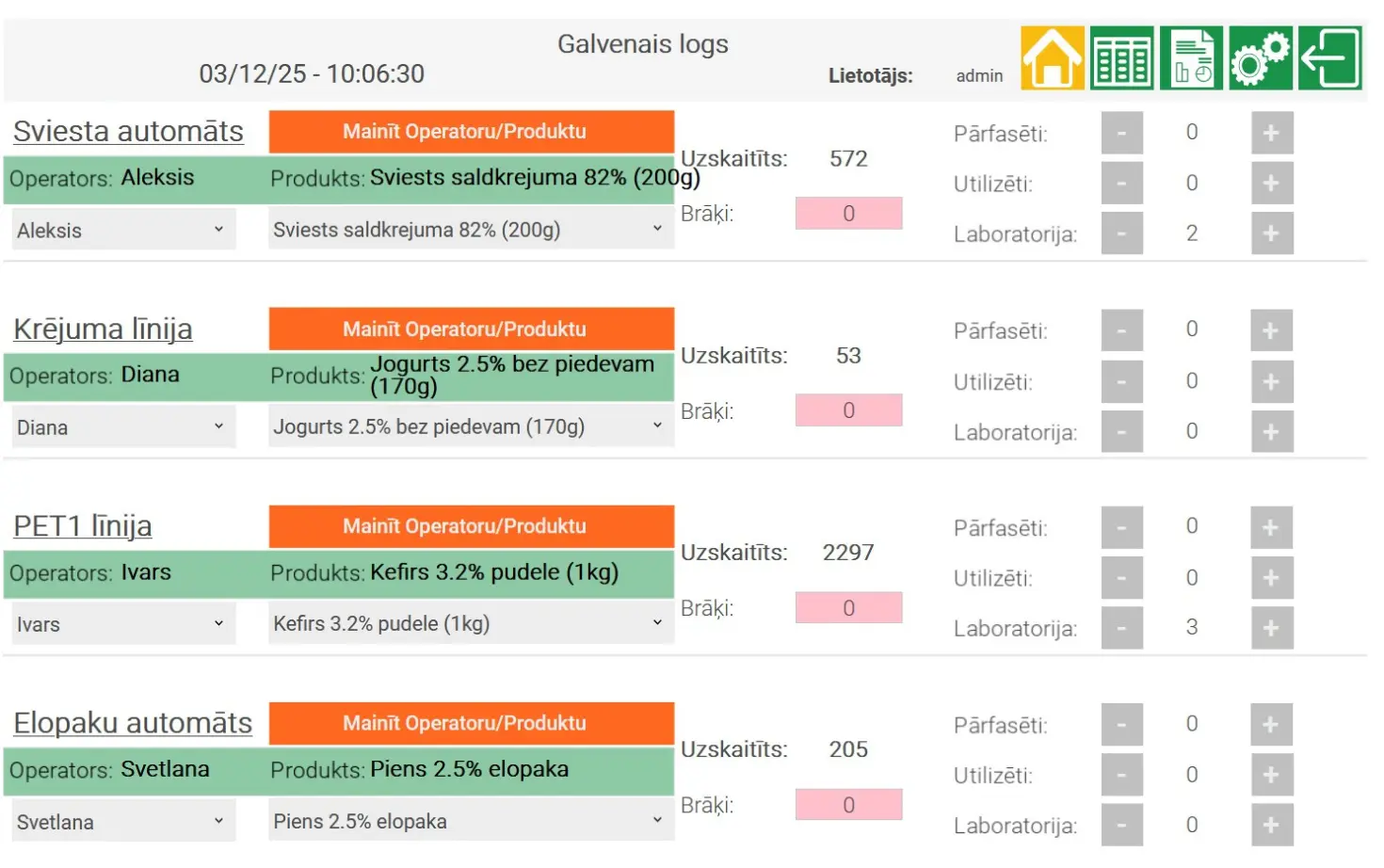

Operator Interface

Operator and Product Selection Screen

At shift start, operator selects themselves from the list, and which product is currently being produced on the line

Production Count and Exception Logging

Real-time display of accumulated product counts, with a dedicated interface for logging defects, reworked items, and products sent to the laboratory.

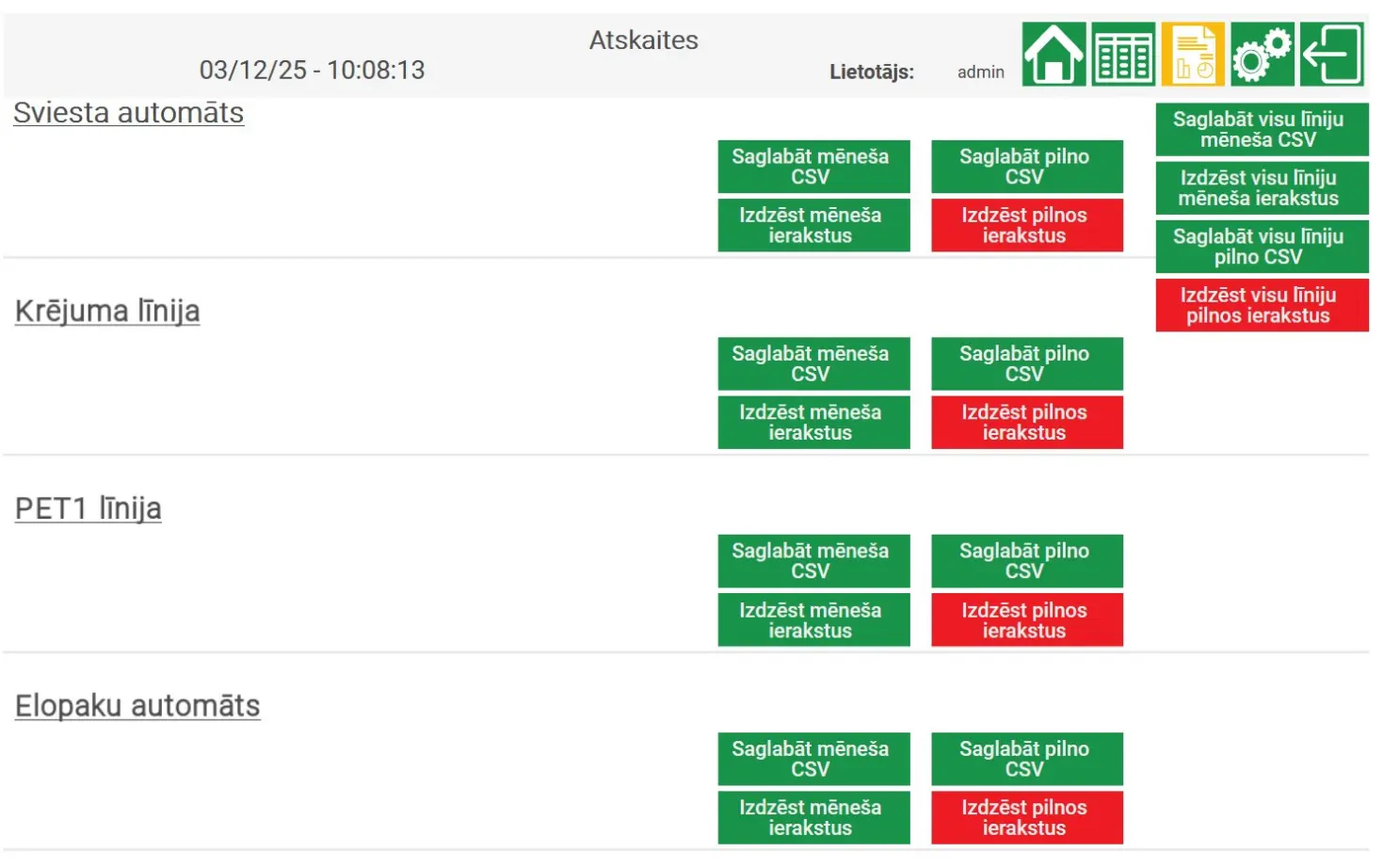

Reports Section

CSV export and filters by date, operator, product

Want a similar solution?

We'll design a customized production monitoring system for you.

Q&A

A 4-line system implementation costs under €10,000. The final price depends on the specific number of lines and required sensors.

Depending on the operator's education level and experience with similar systems – typically 1-2 weeks. The system is designed intuitively to facilitate daily work in the production facility.

If a sensor breaks down, it's simply replaced with a new one.

Yes, the system can be expanded after initial implementation. You can add up to ~49 lines maximum.

However, when expanding the system, you need to consider:

- Product flow speed in each line

- Overall system architecture

We'll help assess the optimal solution for your production facility's specific needs.